Table of Contents

What Makes Quality Trailer Wheels

Before diving into the top manufacturers, it’s essential to understand what distinguishes high-quality trailer wheels from standard options. Premium trailer wheels must meet stringent requirements for durability, load capacity, and safety compliance.

Quality trailer wheels are characterized by several key factors:

- Material Quality: High-grade steel or aluminum alloys that resist corrosion and fatigue

- Manufacturing Precision: Accurate machining and quality control processes

- Load Rating: Appropriate weight capacity for intended applications

- Safety Certifications: Compliance with DOT and international standards

- Surface Treatment: Protective coatings that prevent rust and enhance longevity

Understanding these fundamentals helps explain why certain manufacturers have earned their reputation as industry leaders. For those specifically interested in steel trailer wheels, material composition and treatment processes become even more critical factors.

Top 10 Trailer Wheel Manufacturers

1. Accuride Corporation

With over 100 years of manufacturing experience, Accuride Corporation stands as a global leader in the commercial vehicle wheel industry. Based in Indianapolis, Indiana, the company has built its reputation on producing lightweight steel and forged aluminum wheels that meet the demanding requirements of OEMs, fleets, and aftermarket distributors.

| Specification | Details |

|---|---|

| Founded | 1916 |

| Headquarters | Indianapolis, IN, USA |

| Specialization | Commercial vehicle wheels |

| Primary Materials | Steel, Forged Aluminum |

Accuride’s commitment to innovation has led to breakthrough technologies in wheel lightweighting, which directly impacts fuel efficiency and payload capacity for commercial operators.

2. The Carlstar Group

The Carlstar Group represents a comprehensive approach to specialty tires and wheels, owning several renowned brands including Carlisle®, ITP®, Marathon, Cragar®, and Black Rock®. Their diverse portfolio serves multiple markets from agriculture to power sports.

What sets Carlstar apart is their integrated approach to wheel and tire solutions, providing matched systems that optimize performance across various applications. Their expertise extends to agricultural wheel rims and specialized off-road applications.

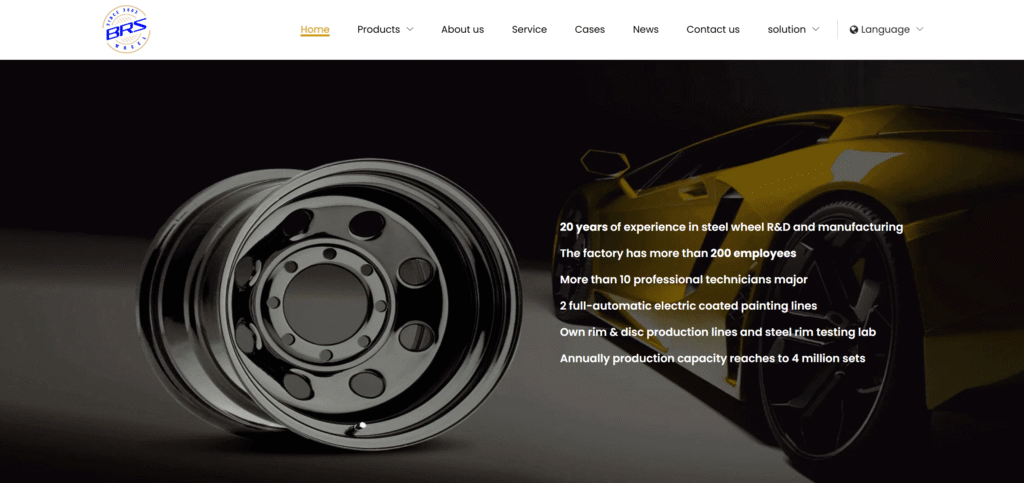

3. Ningbo BRS Auto Parts Co., Ltd

Established in 2002, Ningbo BRS Auto Parts Co., Ltd has grown from a 5,000 square meter facility to over 100,000 square meters, representing one of China’s most significant success stories in steel wheel manufacturing. As the earliest automobile steel wheel manufacturer in China and the first strategic partner of Geely Group, BRS has set industry standards for quality and innovation.

| Company Highlights | Specifications |

|---|---|

| Manufacturing Capacity | 100,000+ square meters facility |

| Workforce | 200+ skilled workers |

| Production Lines | Multiple rim & disc production lines |

| Coating Technology | 2 full-automatic electric coated painting lines |

| Quality Control | In-house wheel testing laboratory |

BRS’s competitive advantages include:

- Precision Engineering: Advanced shot blasting processes ensure smooth surfaces and superior coating adhesion

- Superior Durability: Enhanced corrosion resistance through specialized treatment processes

- Customizable Options: Wide variety of sizes and designs for trailer wheels and off-road applications

- Technical Expertise: Over 10 professional technicians specializing in 2D, 3D, and CAE analysis

For businesses seeking reliable custom steel wheels manufacturers, BRS offers comprehensive OEM and ODM services with rapid response times and competitive pricing.

Contact Information:

Address: 1st, Rili Middle Road, Yinzhou District, Ningbo, China

Phone: +86 19810666863

Email: carrie@brsautoparts.com

Website: brsrim.com

Working Hours: 8:00 – 21:00 Monday to Friday

4. Dexstar Wheel

With over 50 years of manufacturing excellence, Dexstar Wheel has established itself as a premier American manufacturer specializing in high-quality steel wheels for trailer, RV, marine, and mobile home industries. Located in Elkhart, Indiana, the company is renowned for its robust products available in various colors and stripe options.

All Dexstar products meet or exceed DOT standards, ensuring compliance with U.S. Department of Transportation requirements. Their product line includes Mod, Spoke, and Solid Center styles, catering to diverse aesthetic and functional preferences.

5. ConMet (Consolidated Metco, Inc.)

As a subsidiary of Amsted Industries, ConMet provides innovative wheel-end solutions specifically designed for the commercial vehicle market. Based in Vancouver, Washington, the company focuses on durable, long-lasting wheel-end products while also supplying lightweight aluminum castings and plastic components.

ConMet’s expertise extends beyond simple wheel manufacturing to complete wheel-end assemblies, hubs, brake drums, and other critical components that ensure optimal performance and safety in commercial applications.

6. Mullins Wheels

Mullins Wheels brings over a century of Australian manufacturing heritage to the global market. Founded in 1905 as an automotive repair and engineering business, the company has evolved to offer comprehensive wheel solutions for trucks, semi-trailers, mining, construction, and agricultural equipment.

Their product range spans both alloy and steel wheels, with particular expertise in heavy-duty applications that demand exceptional durability and reliability. Mullins also provides trailer axles and components, offering integrated solutions for complete trailer systems.

7. Qingzhou Huamei Wheel Co., Ltd.

Qingzhou Huamei Wheel represents the growing strength of Chinese manufacturing in the global wheel industry. The company focuses on producing reliable, cost-effective wheels that compete effectively in international markets while maintaining quality standards.

Their specialization includes trailer wheels, engineering machinery wheels, and agricultural machinery wheels, serving diverse industrial applications with proven reliability and competitive pricing.

8. Shandong Oasisland Wheel Systems Co., Ltd.

This professional steel wheel manufacturer in China provides comprehensive OEM and ODM services, with products exported worldwide. Their reputation for quality and service has made them a preferred partner for international distributors and manufacturers.

The company produces various sizes of steel wheels and rims suitable for trailers, trucks, and agricultural machinery, emphasizing customization capabilities and responsive customer service.

9. Felling Trailers, Inc.

While primarily known as a trailer manufacturer, Felling Trailers also produces and distributes various trailer components, including wheels. Based in Sauk Centre, Minnesota, they offer custom solutions and are recognized for high-quality, durable products.

Their integrated approach combines trailer manufacturing with component supply, ensuring compatibility and optimal performance across their product ecosystem.

10. Asquare Parts Inc.

Located in Houston, Texas, Asquare Parts Inc. operates as both a wholesale distributor and custom manufacturer of automotive and engineering components. Their broad product range includes U-bolts, rims, hubs, and bearings, serving multiple industries including aerospace, construction, and oil and gas.

This diversity allows them to bring cross-industry expertise to trailer wheel applications, incorporating lessons learned from demanding industrial environments.

How to Choose the Right Manufacturer

Selecting the appropriate trailer wheel manufacturer requires careful consideration of multiple factors that impact both immediate performance and long-term value. Understanding these criteria helps ensure optimal results for your specific application.

Application-Specific Requirements

Different trailer applications demand specific wheel characteristics. Heavy duty 8 lug trailer wheels serve different purposes than standard passenger trailers, requiring manufacturers with appropriate expertise and certifications.

Key application factors include:

- Load capacity requirements

- Operating environment (highway, off-road, marine)

- Frequency of use and duty cycle

- Regulatory compliance needs

- Aesthetic preferences and branding requirements

Quality and Certification Standards

Reputable manufacturers maintain comprehensive quality control systems and relevant certifications. Look for:

- DOT compliance for highway use

- ISO quality management certifications

- In-house testing capabilities

- Traceability systems for quality assurance

- Warranty programs that reflect manufacturer confidence

Manufacturing Capabilities

Assess potential manufacturers’ technical capabilities and capacity to meet your requirements:

| Capability | Importance | Evaluation Criteria |

|---|---|---|

| Production Volume | High | Can meet quantity requirements and delivery schedules |

| Customization | Medium-High | Ability to modify standard products or create custom solutions |

| Material Options | High | Range of steel grades, aluminum options, and surface treatments |

| Technical Support | Medium | Engineering assistance and application guidance |

Industry Trends and Innovations

The trailer wheel manufacturing industry continues evolving, driven by regulatory changes, technological advancement, and market demands for improved performance and sustainability.

Lightweighting Initiatives

Manufacturers increasingly focus on reducing wheel weight without compromising strength or durability. This trend directly impacts fuel efficiency and payload capacity, making it particularly important for commercial operators.

Advanced materials and manufacturing techniques enable significant weight reductions while maintaining or improving performance characteristics. For those considering steel vs aluminum winter rims, understanding these developments helps inform material selection decisions.

Enhanced Corrosion Protection

Improved coating technologies and surface treatments extend wheel life in challenging environments. Modern powder coating systems and specialized primers provide superior protection compared to traditional painting methods.

Smart Manufacturing Integration

Industry leaders incorporate advanced manufacturing technologies including:

- Automated quality control systems

- Predictive maintenance programs

- Real-time production monitoring

- Advanced materials testing

Sustainability Focus

Environmental considerations increasingly influence manufacturing processes and product design. Manufacturers invest in:

- Energy-efficient production methods

- Recycling programs for end-of-life products

- Reduced packaging and shipping impacts

- Environmentally friendly coating systems

Maintenance and Longevity Considerations

Proper maintenance significantly impacts trailer wheel performance and lifespan, regardless of manufacturer quality. Understanding maintenance requirements helps maximize your investment and ensure safe operation.

Regular Inspection Protocols

Implement systematic inspection procedures to identify potential issues before they become serious problems:

| Inspection Item | Frequency | Key Indicators |

|---|---|---|

| Visual Condition | Each Use | Cracks, dents, corrosion signs |

| Fastener Torque | Monthly | Proper lug nut tension |

| Surface Coating | Seasonal | Paint condition, rust formation |

| Professional Inspection | Annual | Structural integrity assessment |

Cleaning and Protection

Regular cleaning removes corrosive materials and maintains appearance. Use appropriate cleaning products that don’t damage protective coatings, and consider protective treatments for harsh environments.

For specific guidance on maintaining different wheel types, resources like 6 powerful ways to clean steel wheels and keep them looking new provide detailed maintenance instructions.

Load Management

Operating within manufacturer specifications prevents premature failure and maintains safety margins. Understand your wheels’ load ratings and ensure proper load distribution across all wheel positions.

Conclusion

The trailer wheel manufacturing industry offers numerous options, each with distinct advantages for specific applications. From established American manufacturers like Accuride and Dexstar to innovative companies like Ningbo BRS Auto Parts, the market provides solutions for virtually every trailer wheel requirement.

Success in selecting the right manufacturer depends on understanding your specific needs, evaluating manufacturer capabilities, and considering long-term factors including maintenance requirements and total cost of ownership. Quality manufacturers like those highlighted in this guide provide not just products, but partnerships that support your operational success.

Whether you need standard replacement wheels or custom solutions for specialized applications, working with reputable manufacturers ensures access to quality products, technical support, and reliable supply chains that keep your operations moving efficiently.

For businesses seeking reliable trailer wheel solutions, consider exploring options from proven manufacturers who demonstrate consistent quality, innovation, and customer support. Companies like BRS Auto Parts offer the technical expertise, manufacturing capacity, and customer service that characterize industry leaders.

To learn more about trailer wheel options and connect with manufacturers, visit boat trailer rims for specialized marine applications or explore the complete range of steel rims available from leading manufacturers.