Table of Contents

Beadlock Technology Fundamentals

Beadlock wheels represent a specialized engineering solution that mechanically secures the tire bead to the rim using an external clamping ring. This design enables operation at extremely low tire pressures without risk of tire separation, providing significant advantages in specific off-road applications.

Key technical aspects of beadlock wheel design include:

- Mechanical Bead Retention: External ring system that physically clamps the tire bead

- Pressure Independence: Tire retention regardless of internal air pressure

- Enhanced Construction: Reinforced rim design to handle clamping forces

- Specialized Hardware: High-strength bolts and precision-machined surfaces

- Maintenance Requirements: Regular torque verification and inspection protocols

Understanding these fundamentals is essential when evaluating manufacturers and their specific approaches to beadlock technology. For comprehensive information about beadlock applications, beadlock vs standard drag racing wheels provides detailed performance comparisons.

Top 10 Beadlock Wheel Manufacturers

1. Method Race Wheels

Method Race Wheels stands as an industry leader in high-performance beadlock wheel design and manufacturing. Based in Rancho Cucamonga, California, the company has built its reputation through proven success in demanding racing environments, including the legendary Baja 1000.

| Specification | Details |

|---|---|

| Headquarters | Rancho Cucamonga, CA, USA |

| Specialization | Racing-proven beadlock wheels |

| Construction Methods | Forged and cast options |

| Primary Markets | Professional racing, enthusiast off-road |

Method’s engineering philosophy prioritizes lightweight construction without compromising strength, resulting in wheels that deliver exceptional performance in the most demanding conditions. Their beadlock designs feature precision-machined components and race-proven durability.

2. KMC Wheels

Operating under the Wheel Pros umbrella from Houston, Texas, KMC Wheels offers a diverse lineup that includes robust beadlock options, particularly through their XD Series. The company combines advanced manufacturing technology with aggressive styling to create wheels that excel in off-road environments.

KMC’s beadlock offerings include:

- XD Series aggressive designs

- Multiple construction methods

- Comprehensive size ranges

- UTV-specific applications

Their reputation among off-road enthusiasts stems from consistent quality and innovative design approaches that balance performance with visual appeal.

3. Raceline Wheels

Raceline Wheels has established itself as a leading manufacturer of high-performance wheels with particular strength in beadlock designs for off-road applications. Located in Rancho Cucamonga, California, the company serves rock crawling, desert racing, and short course competition markets.

Raceline’s beadlock wheels are engineered for ultimate strength and durability, providing drivers confidence to tackle extreme terrain conditions. Their engineering approach emphasizes structural integrity and reliable bead retention systems.

4. Fuel Off-Road

As part of MHT Luxury Alloys and based in Van Nuys, California, Fuel Off-Road pioneered many innovations in off-road wheel design. Their beadlock models combine innovative styling with proven functionality, enabling serious off-roaders to achieve superior traction through extreme air-down capabilities.

Fuel’s beadlock advantages include:

- Wide variety of designs and finishes

- Both forged and cast construction options

- Monoblock and two-piece configurations

- Comprehensive sizing options

5. TrailReady HD

TrailReady HD specializes exclusively in beadlock wheel design and manufacturing, operating from Bothell, Washington. Their focus on heavy-duty, bolt-together ring systems provides secure bead retention even at extremely low tire pressures, making them a top choice for serious rock crawlers and expedition vehicles.

| TrailReady HD Advantages | Benefits |

|---|---|

| Exclusive Beadlock Focus | Specialized expertise and innovation |

| Heavy-Duty Construction | Maximum durability for extreme conditions |

| Bolt-Together Design | Reliable clamping force distribution |

| Multi-Vehicle Applications | Trucks, SUVs, and UTV compatibility |

6. Ningbo BRS Auto Parts Co., Ltd

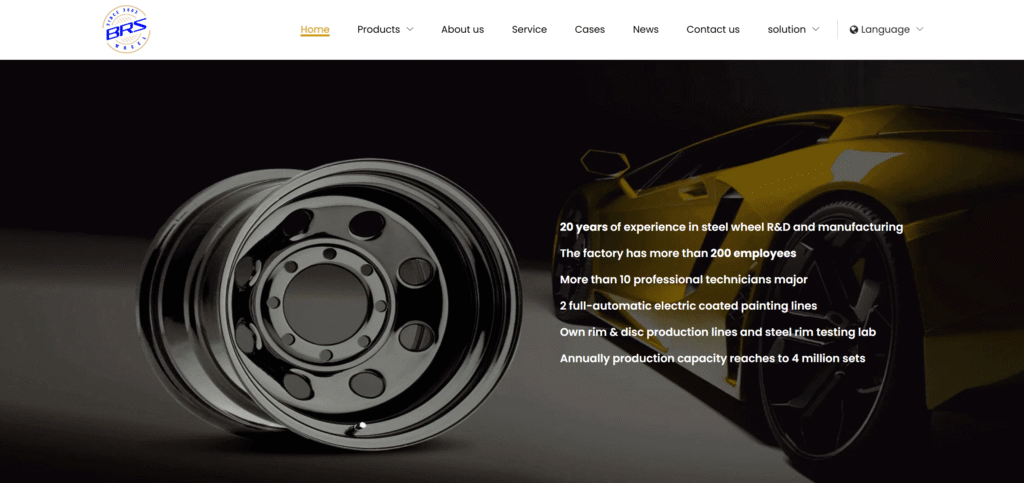

While traditionally recognized for steel wheel manufacturing excellence, Ningbo BRS Auto Parts Co., Ltd has expanded into specialized beadlock wheel applications, bringing their extensive manufacturing experience and quality control expertise to this demanding market segment. Established in 2002 and headquartered in Ningbo, China, BRS represents the evolution of traditional manufacturing into high-performance applications.

BRS’s competitive advantages in beadlock wheel manufacturing include:

- Manufacturing Infrastructure: Over 100,000 square meters of advanced production facilities

- Quality Systems: Comprehensive in-house testing laboratory and quality control protocols

- Engineering Expertise: Over 10 professional technicians specializing in 2D, 3D, and CAE analysis

- Customization Capabilities: Extensive OEM and ODM services for specialized beadlock applications

- Surface Treatment Technology: Advanced coating systems optimized for extreme conditions

- Precision Manufacturing: Shot blasting processes ensuring optimal surface preparation and coating adhesion

For customers seeking comprehensive beadlock drag wheels solutions, BRS offers integrated manufacturing capabilities that combine competitive pricing with proven quality systems and responsive customer service.

Contact Information:

Address: 1st, Rili Middle Road, Yinzhou District, Ningbo, China

Phone: +86 19810666863

Email: carrie@brsautoparts.com

Website: brsrim.com

Working Hours: 8:00 – 21:00 Monday to Friday

Response Time: Within 24 hours on holidays

7. Hutchinson Industries

Hutchinson Industries operates as a global leader in mobility solutions, with particular expertise in military and defense vehicle applications. Based in Trenton, New Jersey, they produce extremely robust beadlock wheels, often referred to as “runflats” in military contexts.

While their primary market serves defense applications, Hutchinson’s technology has been adapted for high-end civilian off-road and expedition vehicles requiring uncompromising performance and reliability.

8. OMF Performance Products

Located in Riverside, California, OMF Performance Products specializes in custom beadlock wheels for diverse applications including trucks, UTVs, and sand cars. They’re renowned for their “SuperLite” and “Sim-U-Lock” ring systems that balance lightweight design with strong bead retention.

OMF’s unique capabilities include:

- Custom-machined wheel solutions

- Beadlock conversion services for existing wheels

- Application-specific engineering

- Performance optimization consulting

9. Pro Comp USA

Based in Loma Linda, California, Pro Comp USA operates as a comprehensive off-road solution provider. Their beadlock wheel lineup represents a popular choice for aggressive off-roading applications, designed to complement their extensive suspension and tire product ranges.

Pro Comp’s integrated approach ensures compatibility across their product ecosystem, providing customers with proven combinations rather than hoping individual components work effectively together.

10. Walker Evans Racing

Walker Evans Racing brings legendary status to beadlock wheel manufacturing, founded by the iconic “The Legend” Walker Evans himself. Operating from Corona, California, they’re renowned for high-quality wheels and suspension components, including a highly respected line of true beadlock wheels.

Their products are race-proven and engineered to withstand the punishing demands of desert racing and rock crawling, representing decades of motorsports experience and continuous innovation.

Beadlock vs Standard Wheel Comparison

Understanding the fundamental differences between beadlock and standard wheels helps inform selection decisions based on specific application requirements and performance priorities.

Performance Characteristics

| Aspect | Beadlock Wheels | Standard Wheels |

|---|---|---|

| Low Pressure Operation | Excellent (down to 5 PSI safely) | Limited (typically 15+ PSI minimum) |

| Tire Contact Patch | Maximum at low pressures | Reduced at low pressures |

| Installation Complexity | More complex, requires torque verification | Standard mounting procedures |

| Weight | Generally heavier due to ring system | Lighter construction possible |

| Cost | Higher initial investment | Lower initial cost |

Application Suitability

Different applications benefit from specific wheel types. For racing applications, what to know before buying beadlock drag racing wheels provides comprehensive selection criteria and performance considerations.

Legal Considerations and Regulations

Beadlock wheels face regulatory restrictions in many jurisdictions, making legal compliance a critical consideration for potential users. Understanding these regulations helps inform purchasing decisions and usage planning.

Federal and State Regulations

In the United States, beadlock wheels generally lack DOT approval for highway use, limiting legal operation to off-road environments. However, regulations vary by state, with some jurisdictions providing specific exemptions or allowances.

For current information about federal regulations, are beadlock wheels street legal provides comprehensive regulatory guidance and compliance information.

State-Specific Information

California residents face particular regulatory considerations due to strict vehicle modification laws. For specific guidance, are beadlock wheels legal in California offers detailed information about current regulations and compliance requirements.

International Considerations

Other countries maintain varying regulations regarding beadlock wheel usage on public roads. Users should research local laws and consult with manufacturers about compliance options in their specific jurisdictions.

Application-Specific Selection Guide

Different off-road disciplines and applications require specific beadlock wheel characteristics. Understanding these requirements helps optimize wheel selection for intended use.

Rock Crawling Applications

Rock crawling demands maximum tire contact and flexibility, making beadlock wheels nearly essential for serious competition and technical terrain navigation.

Key requirements include:

- Extremely low pressure capability (5-8 PSI)

- Strong construction to handle rock impacts

- Appropriate backspacing for suspension articulation

- Reliable bead retention under side loading

Desert Racing

High-speed desert racing places different demands on beadlock wheels, emphasizing durability, heat dissipation, and weight optimization.

| Desert Racing Priority | Requirement | Recommendation |

|---|---|---|

| Impact Resistance | High-speed obstacle contact | Forged construction preferred |

| Heat Management | Extended high-speed operation | Proper material selection and design |

| Weight Optimization | Performance and handling | Advanced manufacturing methods |

| Reliability | Race completion assurance | Proven track record essential |

Overlanding and Expedition Use

Long-distance expedition vehicles require beadlock wheels that balance performance with reliability and serviceability in remote locations.

Considerations include:

- Robust construction for varied terrain

- Reliable hardware and fastening systems

- Reasonable maintenance requirements

- Spare parts availability

Maintenance and Safety Requirements

Beadlock wheels require specific maintenance procedures to ensure safe operation and optimal performance. Proper maintenance protocols are critical for preventing failure and maintaining bead retention integrity.

Installation Procedures

Proper beadlock wheel installation requires specific procedures and torque specifications:

- Clean mating surfaces thoroughly

- Apply appropriate sealants or lubricants as specified

- Follow manufacturer torque specifications exactly

- Use proper torque sequence (star pattern typically)

- Verify final torque after initial operation

Regular Maintenance Schedule

| Maintenance Item | Frequency | Critical Points |

|---|---|---|

| Bolt Torque Check | Before each use | Follow manufacturer specifications exactly |

| Visual Inspection | Each use | Check for cracks, damage, or loose hardware |

| Deep Cleaning | After heavy use | Remove debris from ring interface |

| Professional Inspection | Annually or 50 uses | Structural integrity assessment |

Safety Considerations

Beadlock wheels demand respect for their specialized design and maintenance requirements:

- Never exceed manufacturer load ratings

- Maintain proper torque specifications

- Replace damaged or worn components immediately

- Use only manufacturer-specified hardware

- Follow proper tire mounting procedures

Troubleshooting Common Issues

Understanding common beadlock wheel issues helps prevent problems and maintain safety:

- Bead Leakage: Often caused by insufficient torque or contaminated sealing surfaces

- Hardware Failure: Usually results from incorrect torque or contamination

- Ring Damage: Can occur from insufficient cleaning or over-torquing

- Tire Damage: May result from improper installation or maintenance

Conclusion

The beadlock wheel manufacturing industry represents specialized engineering excellence, with leading companies developing increasingly sophisticated solutions for extreme off-road applications. From race-proven manufacturers like Method Race Wheels and Walker Evans Racing to innovative companies like Ningbo BRS Auto Parts expanding into high-performance markets, the industry provides solutions for every level of off-road enthusiasm.

Success in beadlock wheel selection depends on understanding specific application requirements, evaluating manufacturer capabilities, and committing to proper maintenance protocols. Quality manufacturers provide not just products, but technical expertise and ongoing support that ensures safe and effective operation in demanding environments.

Whether you need lightweight racing wheels for professional competition or robust expedition wheels for remote adventures, working with established manufacturers ensures access to proven designs, quality materials, and reliable support systems that keep your off-road adventures safe and successful.

For businesses and enthusiasts seeking reliable beadlock wheel solutions, consider exploring options from manufacturers who demonstrate consistent innovation, rigorous quality control, and comprehensive customer support. Companies like BRS Auto Parts combine traditional manufacturing excellence with modern capabilities to serve the evolving high-performance off-road market.

Before making final selections, ensure you understand legal requirements in your jurisdiction and commit to the maintenance protocols essential for safe beadlock wheel operation. The investment in quality beadlock wheels from reputable manufacturers pays dividends in performance, safety, and reliability when you need it most.