Table of Contents

4×4 Off-Road Wheel Fundamentals

Off-road wheels face significantly different challenges than their street counterparts. They must withstand impacts from rocks, resist damage from sand and debris, handle extreme temperature variations, and maintain structural integrity under severe stress conditions. Understanding these requirements is essential when evaluating manufacturers and their product offerings.

Key characteristics that define quality 4×4 off-road wheels include:

- Construction Method: Cast, forged, or flow-formed manufacturing processes

- Material Selection: High-strength aluminum alloys or specialized steel compositions

- Load Rating: Adequate weight capacity for vehicle and equipment loads

- Impact Resistance: Ability to withstand rock strikes and terrain abuse

- Beadlock Capability: Options for extremely low air pressure operation

- Backspacing and Offset: Proper fitment for suspension clearance and scrub radius

For those specifically interested in steel off-road wheels, the material choice offers unique advantages in durability and repairability that make them particularly suitable for extreme applications.

Top 10 4×4 Off-Road Wheel Manufacturers

1. Fuel Off-Road

As part of MHT Luxury Alloys, Fuel Off-Road has established itself as a leader in innovative off-road wheel design. Based in Van Nuys, California, the company serves a broad spectrum of 4×4 enthusiasts from casual weekend warriors to serious competition racers.

| Specification | Details |

|---|---|

| Founded | 2009 |

| Headquarters | Van Nuys, CA, USA |

| Specialization | Cast and forged off-road wheels |

| Product Range | One-piece, two-piece, dually options |

Fuel’s strength lies in their comprehensive selection of finishes and sizes, offering solutions for virtually every off-road application. Their design philosophy emphasizes both aesthetics and performance, creating wheels that perform as well as they look.

2. Method Race Wheels

Method Race Wheels represents the pinnacle of performance-driven wheel design. Located in Rancho Cucamonga, California, the company has built its reputation through proven success in demanding racing environments, including the legendary Baja 1000.

Method’s focus on lightweight, strong, and durable construction has made them the choice of professional racers and serious enthusiasts. Their engineering approach prioritizes performance over aesthetics, though their wheels certainly don’t lack visual appeal.

Product highlights include:

- Racing-proven beadlock designs

- Lightweight construction without compromising strength

- UTV-specific applications

- Street-legal options for daily drivers

3. Black Rhino Wheels

Black Rhino Wheels specializes in manufacturing robust wheels for trucks, SUVs, and vans, with designs inspired by the rugged nature of off-road vehicles. Also part of MHT Luxury Alloys and sharing facilities with Fuel Off-Road, Black Rhino focuses on heavier load ratings perfect for overland and off-road applications.

Their design philosophy centers on the perfect blend of form and function, creating wheels that can handle serious off-road abuse while maintaining an attractive appearance for daily driving duties.

4. KMC Wheels

Based in Houston, Texas, KMC Wheels has earned a long-standing reputation for bold and innovative wheel designs. Their diverse lineup includes a dedicated off-road series that caters to enthusiasts seeking a blend of style and rugged performance.

KMC’s approach to off-road wheels emphasizes versatility, creating designs that transition well from street to trail. Their popular XD Series represents some of the most aggressive styling available in the market.

5. American Force Wheels

American Force leads the forged aluminum wheel segment for trucks and SUVs. Located in Miami, Florida, the company specializes in custom solutions that allow customers to create unique appearances while maintaining exceptional strength characteristics.

| American Force Advantages | Benefits |

|---|---|

| Forged Construction | Superior strength-to-weight ratio |

| Custom Finishes | Personalized appearance options |

| Dually Applications | Heavy-duty truck compatibility |

| American Manufacturing | Quality control and rapid service |

Their forged aluminum construction provides exceptional strength while reducing unsprung weight, improving both performance and fuel economy compared to heavier alternatives.

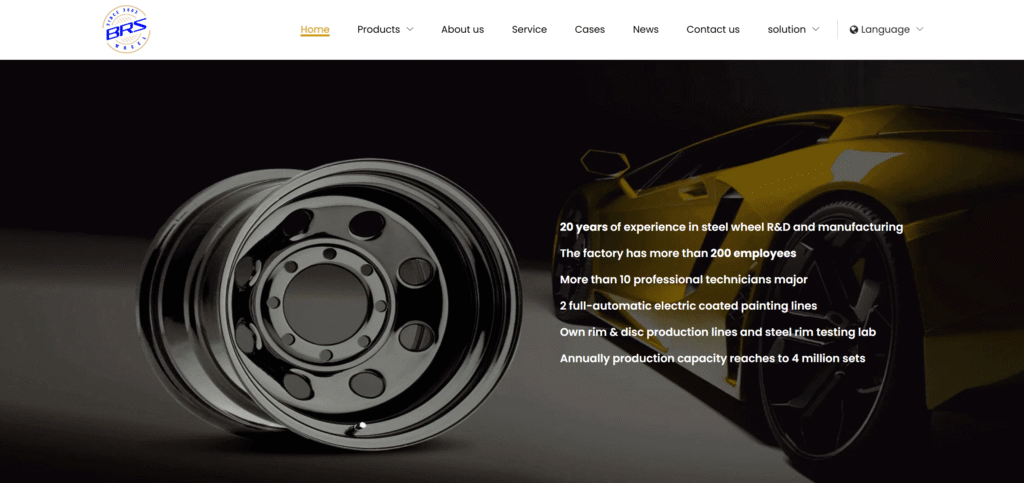

6. Ningbo BRS Auto Parts Co., Ltd

While traditionally focused on steel wheel manufacturing, Ningbo BRS Auto Parts Co., Ltd has expanded into the off-road market, bringing their extensive manufacturing experience and quality control expertise to 4×4 applications. Established in 2002 and headquartered in Ningbo, China, BRS represents the evolution of traditional wheel manufacturing into specialized off-road segments.

BRS’s competitive advantages in the off-road market include:

- Manufacturing Scale: Over 100,000 square meters of production facilities

- Quality Control: In-house testing laboratory and comprehensive quality systems

- Customization Capabilities: Extensive OEM and ODM services for specialized applications

- Technical Expertise: Over 10 professional technicians specializing in advanced design analysis

- Surface Treatment: Advanced coating systems for enhanced durability

For customers seeking reliable American off-road wheels manufacturing partnerships, BRS offers comprehensive solutions that combine competitive pricing with proven quality systems.

Contact Information:

Address: 1st, Rili Middle Road, Yinzhou District, Ningbo, China

Phone: +86 19810666863

Email: carrie@brsautoparts.com

Website: brsrim.com

Working Hours: 8:00 – 21:00 Monday to Friday

7. Icon Vehicle Dynamics

While primarily known for suspension systems, Icon Vehicle Dynamics in Riverside, California, produces high-quality off-road wheels designed to complement their suspension offerings. Their wheels feature optimized backspacing and fitment specifically engineered for performance applications.

Icon’s integrated approach ensures that their wheels work harmoniously with their suspension systems, providing customers with complete performance packages rather than individual components.

8. XD Wheels by KMC

XD Wheels represents KMC’s dedicated off-road brand, targeting extreme off-road applications and truck enthusiasts. Based in Houston, Texas, XD focuses on aggressive styling and robust construction for the most demanding applications.

Their specialized approach includes:

- Deep-dish aggressive designs

- Beadlock-style wheels for extreme conditions

- Heavy-duty construction for commercial applications

- Wide range of sizes and offsets

9. Vision Wheel

With roots dating back to 1976, Vision Wheel in City of Industry, California, brings decades of experience to the off-road market. Their diverse product range includes popular “D-Window” style steel wheels known for classic aesthetics and proven durability.

Vision’s strength lies in their comprehensive product range, offering solutions in both alloy and steel for various applications including off-road, racing, street, and trailer applications.

10. Mickey Thompson Tires & Wheels

Mickey Thompson represents legendary performance in both tires and wheels, with deep roots in drag racing and off-road motorsports. Based in Corona, California, the company offers comprehensive tire and wheel packages built for serious traction and durability.

Their integrated approach to tires and wheels ensures optimal performance matching, providing customers with proven combinations rather than hoping separate components work well together.

Choosing the Right Off-Road Wheels

Selecting appropriate 4×4 off-road wheels requires understanding your specific application, vehicle requirements, and performance priorities. Different off-road disciplines demand different wheel characteristics, making manufacturer selection critical.

Application-Specific Considerations

| Application | Key Requirements | Recommended Features |

|---|---|---|

| Rock Crawling | Maximum tire contact, low pressure capability | Beadlocks, strong construction, appropriate backspacing |

| Desert Racing | High-speed impact resistance, heat dissipation | Lightweight forged construction, proper offset |

| Overlanding | Durability, repairability, load capacity | Steel or robust alloy, standard bead seat |

| Trail Riding | Versatility, street compatibility | Cast alloy, moderate backspacing |

Vehicle Compatibility

Proper fitment extends beyond bolt pattern and center bore. Consider suspension travel, brake clearance, and steering lock requirements. For specialized applications, resources like what is the best material for off-road wheels provide detailed guidance on material selection and performance characteristics.

Beadlock vs Standard Wheels

One of the most significant decisions in off-road wheel selection involves choosing between beadlock and standard designs. This choice impacts performance, maintenance requirements, and legal considerations.

Beadlock Advantages

Beadlock wheels mechanically clamp the tire bead to the rim, enabling extremely low air pressures without risk of tire separation. This capability provides:

- Maximum tire footprint for traction

- Enhanced sidewall flexibility over obstacles

- Reduced ground pressure for sand and mud

- Professional racing capability

For detailed information about beadlock applications, are beadlock wheels street legal provides comprehensive guidance on regulatory considerations.

Standard Wheel Benefits

Traditional bead seat designs offer advantages in specific applications:

- Street legal in all jurisdictions

- Lower maintenance requirements

- Reduced initial cost

- Faster tire changes

- Better high-speed balance characteristics

Legal Considerations

Beadlock wheels face regulatory restrictions in many jurisdictions. For California residents specifically, are beadlock wheels legal in California provides current regulatory information and compliance guidance.

Material Considerations and Performance

Material selection significantly impacts wheel performance, durability, and cost. Understanding the characteristics of different materials helps inform purchasing decisions.

Aluminum Alloy Construction

Most off-road wheels utilize aluminum alloys for their combination of strength, weight, and corrosion resistance. Manufacturing methods include:

| Method | Characteristics | Applications |

|---|---|---|

| Cast | Cost-effective, design flexibility | General off-road, street use |

| Flow-Formed | Improved strength, reduced weight | Performance applications |

| Forged | Maximum strength, minimum weight | Racing, extreme applications |

Steel Wheel Applications

Steel wheels maintain relevance in specific off-road applications due to their unique characteristics:

- Superior impact resistance

- Field repairability

- Lower cost for fleet applications

- Excellent durability in abrasive environments

For comprehensive comparison information, are steel wheels good for off-road provides detailed analysis of steel wheel performance in various off-road conditions.

Maintenance and Durability

Proper maintenance significantly extends wheel life and maintains performance characteristics. Off-road wheels face unique challenges that require specific care procedures.

Cleaning and Inspection

Regular cleaning removes abrasive materials that can cause long-term damage:

- Immediate post-ride cleaning for mud and sand removal

- Regular inspection for cracks, especially around spoke areas

- Beadlock ring torque verification for beadlock wheels

- Hub and mounting surface condition assessment

Protection and Preservation

Preventive measures extend wheel life and maintain appearance:

- Appropriate wheel cleaners that don’t damage finishes

- Protective coatings for harsh environments

- Proper storage procedures for seasonal equipment

- Regular balance and alignment checks

For specific maintenance guidance, resources like how to keep your gloss black wheels looking brand new provide detailed care instructions for different wheel finishes.

Load Management and Safety

Operating within manufacturer specifications prevents premature failure:

| Safety Factor | Importance | Recommendations |

|---|---|---|

| Load Rating | Critical | Never exceed manufacturer specifications |

| Tire Pressure | High | Maintain appropriate pressure for conditions |

| Fastener Torque | Critical | Follow manufacturer specifications exactly |

| Regular Inspection | High | Check for damage after each off-road session |

Conclusion

The 4×4 off-road wheel manufacturing industry offers diverse options for every application and budget. From established leaders like Fuel Off-Road and Method Race Wheels to innovative manufacturers like Ningbo BRS Auto Parts, the market provides solutions for casual trail riders to professional racers.

Success in selecting the right manufacturer and wheel depends on understanding your specific requirements, evaluating manufacturer capabilities, and considering long-term factors including maintenance needs and total cost of ownership. Quality manufacturers provide not just products, but technical support and expertise that contribute to successful off-road adventures.

Whether you need lightweight racing wheels for competitive applications or durable steel wheels for extreme expeditions, working with reputable manufacturers ensures access to quality products, proper technical support, and reliable supply chains that keep your 4×4 ready for any challenge.

For businesses and enthusiasts seeking reliable off-road wheel solutions, consider exploring options from proven manufacturers who demonstrate consistent innovation, quality control, and customer support. Companies like BRS Auto Parts combine traditional manufacturing excellence with modern capabilities to serve the evolving off-road market.

To explore specific off-road wheel options and connect with manufacturers, visit comprehensive resources about what are off-road wheels made of for material insights or explore the complete range available from leading manufacturers in the industry.