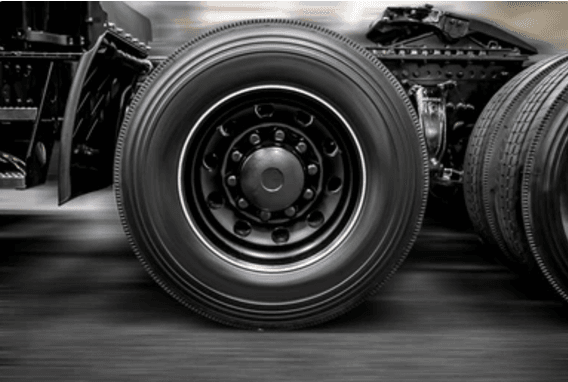

Black Chrome Wheels Recommended by BRS

We’re proud to offer BRS lineup of industry-leading chrome wheels to you. Since its founding, BRS has been building rims that offer stellar strength, design quality, and durability to help you keep moving forward through any situation. BRS provides professional and customized black chrome steel wheels for different models to meet the needs of various users.

Experienced team

good after-sales service

high-quality products