No, not all trailer rims are the same. Bolt patterns, rim sizes, and load ratings vary. Choosing the right trailer rims is crucial. Some people mix tires with different tread depths or even different trailer wheels. This can lead to faster tire wear and increased maintenance costs. Choosing the right rims helps avoid these problems and ensures the safety of every trailer on the road.

Key Takeaways

- Trailer rims are not all the same. Always check the bolt pattern, size, and load rating before purchasing.

- Measuring the rim diameter and width is important. This helps ensure proper fitment and safe operation.

- Choosing the correct load rating for your trailer rims is crucial. It prevents tire problems and improves safety.

- Custom rims are available if needed. Companies like BRS Steel Wheels can custom Boat trailer rims to your specifications.

- Consulting an expert can help you avoid costly mistakes. Getting professional advice helps you choose the best rims for your trailer.

Trailer Rim Compatibility Factors

Trailer rims Bolt Pattern Variations

The bolt pattern plays a significant role in trailer rim compatibility. Each trailer wheel is attached to the hub using a specific number of bolts arranged in a circular pattern. The most common patterns include 4-hole, 5-hole, 6-hole, and 8-hole designs. For example, light-duty utility trailers typically use 4-hole or 5-hole hubs, while heavy-duty commercial trailers rely on 8-hole patterns for added strength. Common bolt patterns for smaller trailers include 4-hole 4-inch and 5-hole 4-1/2-inch. Larger trailers require more bolts to distribute weight and improve safety.

Measuring the bolt pattern is crucial. If the pattern doesn’t match, the rim will not fit onto the hub. BRS Steel Wheels offers a variety of bolt patterns and can custom-make rims to fit almost any trailer. This flexibility helps owners avoid costly mistakes and ensures a safe fit every time.

Rim Size and Diameter

Rim size and diameter affect a trailer’s handling and load-carrying capacity. In North America, the most common trailer rim diameters are as follows:

- 13 inches

- 14 inches

- 15 inches (most common size)

- 16 inches

Rim widths typically correspond to these diameters, ranging from 13 inches to 16 inches. Choosing the correct size helps maintain trailer stability and prevents tire wear. BRS Steel Wheels offers rims from 6 inches to 18 inches, providing trailer owners with a wide range of options to suit various applications.

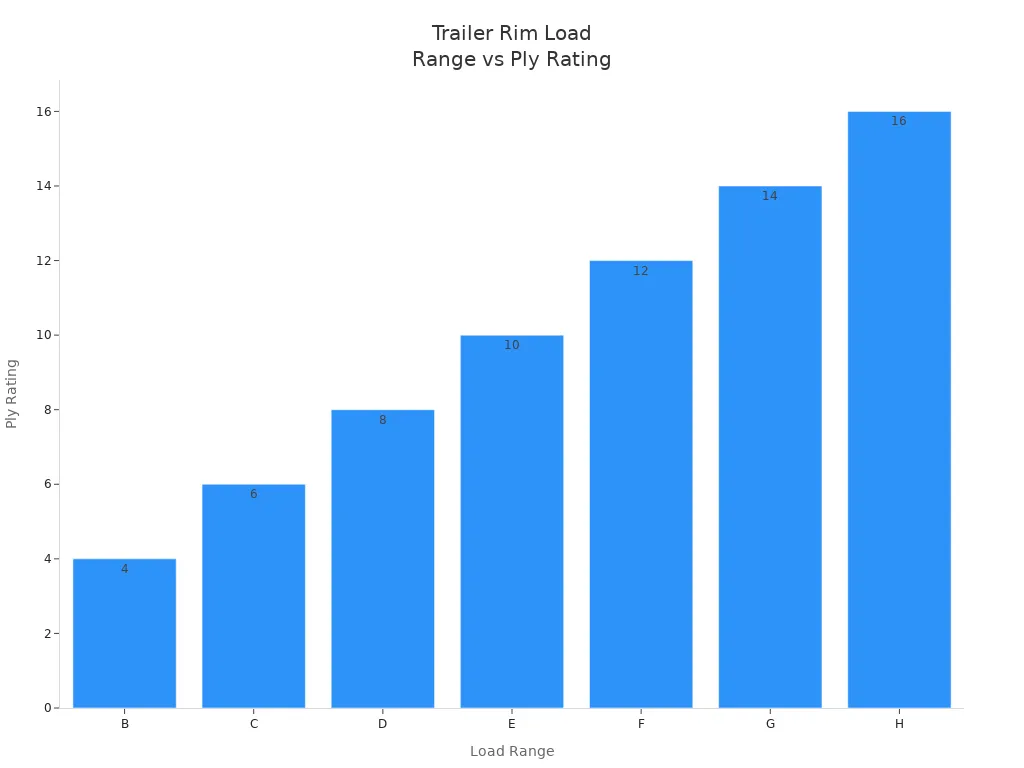

Trailer rims Load Rating

The load rating indicates the maximum weight a trailer rim can safely support. Using rims with a low load rating can lead to tire failure, blowouts, and even loss of control. Matching the rim’s load rating to the trailer’s weight is crucial for safety. The table below shows common load ranges and their typical uses:

| Load Range | Ply Rating | Typical Use |

|---|---|---|

| B | 4-ply | Smaller trailers with lower load requirements |

| C | 6-ply | Medium-sized trailers |

| D | 8-ply | Larger trailers or heavier loads |

| E | 10-ply | Heavy-duty trailers or commercial applications |

| F | 12-ply | Hefty trailers, such as large RVs |

| G | 14-ply | Commercial transport trailers |

| H | 16-ply | Hefty trailers, such as large RVs |

Choosing the appropriate ply rating ensures the trailer travels safely on the road. BRS Steel Wheels offers rims with various load ratings, so every trailer can get the support it needs.

Trailer rims Center Bore and Offset

The center bore is the hole in the middle of the rim, used for mounting onto the hub. If the center bore is too small, the rim will not fit. If the center bore is too large, the rim may not be properly centered, leading to vibration. Offset refers to the distance between the mounting surface and the centerline of the rim. The correct offset ensures that the trailer wheels are properly mounted under the trailer, improving stability and handling.

BRS Steel Wheels can customize the center bore and offset to match any trailer. Our attention to detail ensures the best fit and performance for every customer.

Tip: Before purchasing new trailer rims, be sure to check the bolt pattern, rim size, load rating, center bore, and offset. BRS Steel Wheels’ custom solutions make it easy to get the perfect rims for any trailer.

Common 5-Lug Bolt Patterns Trailer rims

Identifying Your Bolt Pattern

Some trailer owners believe that all 5-hole rims will fit any hub. This is not true and can lead to problems. Not all 5-hole bolt patterns are the same. Each manufacturer produces hubs with their own unique pattern. This helps ensure the rim is properly installed and functions correctly. In the US and Australia, the most common 5-hole bolt pattern is 5 holes on a 4.5-inch diameter circle. However, other patterns exist. Mixing different patterns can result in the rim not fitting or being damaged.

The table below shows common five-hole bolt patterns for trailer hubs:

| Attribute | Details |

|---|---|

| Tire Size | 15″ |

| Nominal Width | 6″ |

| Bolt Pattern | 5 holes on 4.5″ diameter |

| Center Pilot Diameter | 2.62″ |

| Offset/Inset | .50″ (positive offset) |

| Weight Rating | 1820 pounds @ 75 psi |

To find the correct five-hole bolt pattern, follow these steps: Count the number of bolt holes on the hub. Use a ruler, tape measure, or caliper to measure the bolt circle diameter. For a five-hole pattern, measure the distance from the back of one bolt to the center of the bolt directly opposite it.

BRS Steel Wheels can manufacture hubs to fit any common five-hole bolt pattern. Their team can help customers select the right hub and avoid mistakes.

Trailer rims Ford vs. Holden Patterns

Ford and Holden have different five-hole bolt patterns. Ford hubs typically use a 5-hole 4.5-inch pattern. Holden hubs may use a 5-hole 4.75-inch or other size pattern. These subtle differences are crucial. Using the wrong hub can lead to trailer wobble, poor handling, and even wheel detachment.

The table below explains why choosing the correct five-hole bolt pattern is essential:

| Aspect | Explanation |

|---|---|

| Safety | The correct bolt pattern evenly distributes weight. This reduces the likelihood of problems with the bolts or wheels. |

| Performance | The wrong pattern can lead to wobbling, uneven tire wear, and poor braking. |

| Compliance | Using the wrong hub may violate regulations or void warranties. |

BRS Steel Wheels manufactures wheels for Ford, Holden, and other brands. Their expertise ensures each wheel is a perfect match. Owners using BRS products get the right wheels and ensure the safety of their trailers.

Tip: Always check the five-hole bolt pattern before buying new wheels. BRS Steel Wheels’ custom wheels can match any trailer hub.

Choosing the Right Trailer Rims

Measuring Trailer rims for Fit

Before choosing trailer wheels, you need to measure carefully. First, count how many bolt holes are on the hub. Next, use a ruler or caliper to measure the bolt circle diameter. Check the center bore size to ensure it matches the hub. Also measure the diameter and width of the wheel. These steps will help you avoid mistakes and ensure a perfect fit.

Tip: Always double-check your measurements before buying new rims. Choosing the right rim size ensures your trailer runs safely and reliably.

Checking Load and Size Specs

Choosing rims with the correct load rating and size ensures trailer safety. Using unsuitable rims can lead to serious problems:

- Increased risk of tire damage

- Poor trailer handling

- Safety hazards when towing

- Tire overheating

- Uneven tire wear

- Increased risk of blowouts or damage to the axle and suspension

Check the weight of your trailer and choose rims with a matching load rating. Select the appropriate rim size and width for your tires. Doing so helps protect your trailer and the safety of everyone on the road.

Customization Options Trailer rims

Some trailer owners want wheels that are cooler-looking or offer better performance. BRS offers custom steel wheel services for trailers. You can choose your preferred size, design, and finish. Here are some common ways to customize your wheels:

| Customization Aspect | Description |

|---|---|

| Size | You can change the size to fit your needs |

| Design | There are different designs for your style |

| Finish | Many finishes make rims last longer and look good |

The manufacturing time for custom wheels at BRS is approximately: 45 to 60 days for steel wheels, and 30 to 45 days for trailer wheels. People order custom wheels to improve their trailer’s appearance, performance, handling, load capacity, ground clearance, or to easily change tires for different seasons.

Note: BRS’s custom trailer wheels are safe, stylish, and durable. Their team will help each customer find the most suitable wheels.

Myths About Trailer Rim Universality

Misconceptions About Trailer rims Standard Sizes

Some people believe that all trailer wheels with the same bolt pattern are compatible with any trailer. This is a misconception and can lead to wasted money. Wheels may look similar, but they differ in details. These differences affect the wheel’s performance. Owners might see two wheels with five bolts and assume they are a match. But they overlook some important details.

- Diameter affects how the wheel fits the tire and the trailer.

- Width affects the trailer’s stability and tire wear.

- The bolt pattern determines whether the wheel matches the hub bearing.

- Load rating indicates the maximum weight the wheel can handle.

- Wheel type, such as spoke or modular, affects its appearance and installation.

- The center bore must match the hub bearing for proper installation.

- Backspacing and offset affect the wheel’s position under the trailer.

- Material, such as steel or aluminum, affects the wheel’s strength and durability.

If people ignore these details, they may purchase unsuitable or unsafe wheels. Checking all the details before purchasing ensures the wheels are a proper fit and the trailer functions correctly.

Note: Wheels that look the same may not be suitable for your trailer. Always check all the details before purchasing.

Trailer rims Risks of Wrong Fit

Choosing the wrong trailer wheels can lead to serious problems. Sometimes, owners use wheels that are not suitable for their trailers. This can lead to tire failure, blowouts, or tread separation. Sometimes, the trailer can overturn or be damaged. One report stated that a trailer tire’s tread separated and struck another vehicle. These stories illustrate the importance of proper wheel matching.

- Tire failure can cause the trailer to break down.

- Overturning can damage the trailer and its cargo.

- Property damage means more repair costs.

- Flying tire treads can hit other vehicles.

In these cases, no one was injured or killed, but the risks are still high. Those who want to tow safely need to check the wheel specifications before purchasing. BRS offers advice and custom wheels to help customers avoid these problems.

Tip: Always ensure that the wheel size, bolt pattern, load rating, and other details match your trailer. This ensures the safety of your trailer and protects your property.

Tips for Buying Trailer Rims

What to Check Before Purchase

People get excited when buying new trailer wheels. They want their trailers to look good and perform well. Savvy shoppers check several important things before buying. If you skip these steps, you may encounter problems later.

Key checks before buying trailer wheels:

- Ensure the bolt pattern matches the hub, especially for five-hole wheels.

- Measure the rim diameter and width to match the tires.

- Check the load rating to ensure the wheels can handle the trailer’s weight.

- Check the offset and backspacing to ensure safe driving.

- Ensure the tires match the rims for a smooth ride.

- Check the wheel material to ensure durability.

- Check that the rims comply with legal and safety regulations.

Tip: Don’t sacrifice function for aesthetics. If you ignore the offset or backspacing, your trailer may handle poorly. If you don’t check for tire compatibility, you may damage your trailer. If you don’t understand the wheel material, the rims may not be durable. If you ignore safety checks, you may endanger yourself.

When to Get Expert Help

Some people are unsure which type of rim to buy. They may need custom rims or require assistance for a special trailer. Companies like BRS have expert trailer wheel specialists. Their team provides comprehensive service to customers from start to finish.

| Service Type | Description |

|---|---|

| Needs Analysis | Experts communicate with customers to understand the type of trailer rims they need. |

| Needs Analysis and Quotation | Experts research customer needs and provide a quote for custom rims. |

| Product Development | Designers create rims that are high-performing and reasonably priced. |

| Manufacturing | The company manufactures the rims and conducts quality checks at every stage. |

| Inspection and Delivery | Staff inspect and package the rims to ensure safe delivery. |

| After-sales Service | The after-sales support team provides assistance after you receive your rims. |

Note: If you need custom rims or have special requirements, seek professional help. BRS helps customers avoid mistakes and find the most suitable rims for their trailers.

Trailer rims are not universal. Owners need to consider several factors before purchasing. Experts say the following points are crucial:

- The rim diameter should match the tire size.

- The bolt pattern must match the axle.

- The width must match the tire specifications.

- The offset helps to position the wheel correctly.

Choosing the right trailer rims ensures the safety and proper functioning of your trailer. If you need custom rims, contact a company like BRS for expert assistance.

FAQ

Why are trailer rims not universal?

Many factors contribute to the differences in trailer rims. Bolt patterns, rim size, and load ratings all affect rim compatibility. Owners must check these details before purchasing. BRS Steel Wheels provides custom solutions for any trailer.

Can car rims be installed on a trailer?

Most car rims are not suitable for trailers. Trailers have different hub and load requirements than cars. Using the wrong rims can lead to safety issues. Always choose rims specifically designed for trailers.

How do I measure the bolt pattern of a trailer rim?

- Count the number of bolt holes.

- For 5-hole rims, measure the distance from the back of one hole to the center of the opposite hole.

- Use a ruler or caliper for accurate measurements.

Does BRS offer custom trailer wheel rims?

| Feature | BRS Steel Wheels |

|---|---|

| Custom Sizes | ✅ |

| Custom Colors | ✅ |

| Fast Lead Time | ✅ |

BRS offers custom steel trailer wheel rims. Their team helps vehicle owners choose the right size and style.